Wood Chips

Our Products

Wood Chips

Wood chips used as a biomass solid fuel and are raw material for producing wood pulp. They may also be used as an organic mulch in gardening, landscaping, and ecosystem restoration; in bioreactors for denitrification; and as a substrate for mushroom cultivation.

The process of making woodchips is called wood chipping and is done using a wood chipper. The types of woodchips formed following chipping is dependent on the type of wood chipper used and the material from which they are made. Wood chips varieties include: forest chips (from forested areas), wood residue chips (from untreated wood residues, recycled wood and off-cuts), sawing residue chips (from sawmill residues), and short rotation forestry chips (from energy crops).

Preliminary qualification

Wood chips are small- to medium-sized pieces of wood formed by cutting or chipping larger pieces of wood such as trees, branches, logging residues, stumps, roots, and wood waste.

- Calorific Value (ARB) : 4,000 – 4,800 Kcal/kg

- Ash : ≤ 2% (by weight)

- Total Moisture (ARB) : 8% ±3% (by weight)

Other Products

Wood chips used as a biomass solid fuel and are raw material for producing wood pulp. They may also be used as an organic mulch in gardening, landscaping, and ecosystem restoration; in bioreactors for denitrification; and as a substrate for mushroom cultivation.

The process of making woodchips is called wood chipping and is done using a wood chipper. The types of woodchips formed following chipping is dependent on the type of wood chipper used and the material from which they are made. Wood chips varieties include: forest chips (from forested areas), wood residue chips (from untreated wood residues, recycled wood and off-cuts), sawing residue chips (from sawmill residues), and short rotation forestry chips (from energy crops).

Preliminary qualification

Wood chips are small- to medium-sized pieces of wood formed by cutting or chipping larger pieces of wood such as trees, branches, logging residues, stumps, roots, and wood waste.

- Calorific Value (ARB) : 4,000 – 4,800 Kcal/kg

- Ash : ≤ 2% (by weight)

- Total Moisture (ARB) : 8% ±3% (by weight)

Generally, industrial analysis includes the measure of moisture, ash, volatiles, fixed carbon, ash fusion point, total sulfur content, and calorific value. According to the industrial analysis, we can learn about the content of organic matter and the calorific value, so as to identify the type, purpose, and utilization effect of the wood pellets.

Moisture content

Wood pellets are porous solid, with high or low moisture content. The moisture content has great effect on the thermo-chemical conversion of the wood pellets. Therefore, moisture content is one of the basic indicators to identify the wood pellet quality. Over-high moisture content will influence the calorific value and heat efficiency. According to EN plus standard, the moisture content of qualified wood pellets should be lower than 10%

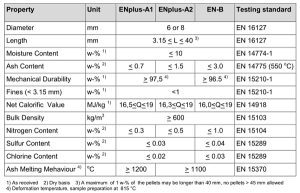

Ash refers to residues after full combustion of wood pellets, generated by the complex reactions such as decomposition and combination of all combustible matters and minerals in wood pellets. Ash content and impurities in the wood pellets have great effect on the coking of boilers. According to EN plus standard, wood pellets fall into 3 grades according to the ash content. The grade A1 has the ash content lower than 0.7%, A2 lower than 1.5%, and grade B lower than 3%.

Volatiles

Volatiles are the decomposed and precipitated organic matters generated under high heat, when the wood pellets burn in isolation from the air. Usually, the higher the volatiles content, the better the combustion effect.

Fixed carbon

The fixed carbon is the residues of wood pellets with the moisture, ash and volatiles removed. The same as ash, fixed carbon is a thermal decomposition product, not a inherent content in biomass pellets. Fixed carbon contains not only carbon, but also hydrogen, oxygen, nitrogen, sulfur, etc. The lower the fixed carbon content, the easier the wood pellets burns, and the less carbon emission.

Calorific value

Wood pellet calorific value includes net calorific value and gross calorific value. The units are Mg/kg.

Gross calorific value (Qgr) refer to all heat generated by the full combustion of 1kg wood pellets, including the latent heat of vaporization when the water vapor in smoke condenses into water. Net calorific value (Qnet) equals the gross calorific value deducts the latent heat of vaporization. In the transaction and use of wood pellets, people usually adopt net calorific value as the measure of calorific value.

Total sulfur content

In the processing of wood pellets, the sulfur content has been reduced to a rather low degree. Qualified wood pellet should have sulfur content lower than 0.07%. According to EN plus standard, grade A1 and A2 wood pellets have sulfur content less than 0.03%, and grade B is less than 0.04%. The sulfur content in wood pellets can meet the environmental standard of the country.

Wood pellet inspection is important for sellers and buyers to confirm the quality of wood pellets. Besides, The wood pellets used in industrial boilers should meet the following standard:

- The diameters are 6-10mm

- The length is 4-5 times that of the diameter.

- The bulk density is more than 600kg/m3.

- The wood pellet density is 1.1-1.4kg/m3, but 0.8-1.1kg/m3 is more economical in industrial boilers.

- The crushing rate is less than 1.5%-2.0%.

- The moisture content of dry base is less than 10%-15%.

- The ash content is less than 1.5%.

- The sulfur content and chlorine content are both less than 0.07%.

- The nitrogen content is less than 0.5%.

- EU doesn’t have specific requirement on the calorific value, but according to the Swedish standard, the calorific value of wood pellets should be higher than 16MJ/kg.

Charcoal Briquettes

Charcoal briquettes are a popular high-end raw material made from 100% wood sawdust. The sawdust is compressed, heated, and compacting into pellets.

Wood Pellets

Wood Pellets is an innovative biomass fuel in the form of solid fuel produced from hardwood from farm trees and weeds to reduce waste.

Wood Chips

Wood chips are biomass fuel from wood processing plants. it is chopped to about 1-2 inches size, which is suitable for using for efficient combustion.

Products Inspection

Scheduling An Appointment

Feel free to contact us scheduling an appointment anytime you need, We Always Welcome...